Water Heaters & Storage Tanks And Their Protective Coating

July 2, 2019

Boiler vs. Furnace: Which is better for your Home?

July 15, 2019The Lithe and Benign Addition to Manufacturing

Manufacturing industry that is automated has many processes with numerous complexities and a singular explanation cannot become the solution for all the issues faced. The range starts from insect sized robots called the Microrobots to the huge industrial robots that are dominant enough to displace an airplane. Of all the robots the most preferred nowadays by most industries are the refined robots called the collaborative robots or Cobots. The Cobots are designed in a way to work hand-in-hand with humans in a shared area of work. Cobots set the foundation for automation in many small and medium sized enterprises, giving even these SMEs to have an opportunity to start the process of automation, which was initially possible only by large-scale industries. Cobots are every startup’s stepping stone towards automation.

It is important for manufacturing industries to understand the advantages and disadvantages of the types of robotics available to make the best choice for their business.

Cobots Proposal to Manufacturers

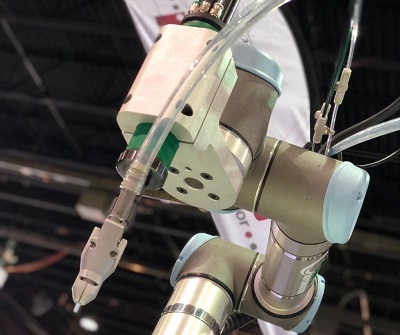

In every industry or manufacturing unit, every employee desires to have an extra helping hand so as to efficiently complete the work process. This helping hand is replaced with collaborative robots, which are much more than just a helping hand. Their technology based arms have in-built motion sensors, cameras and they are premeditated to serve different ranges and consignments. Industries are used to machines doing just one job but Cobots go a step ahead in technology by its ability to conduct multiple and repetitive tasks such as assembling wheels and reviewing small parts of automation. This will thus help release workers from doing the monotonous job and concentrate on fast-growing competent jobs. Instead of just being assigned to drive a forklift, their expertise can be used in other challenging tasks.

Cobot’s expertise in handling packaging of goods in manufacturing is tremendous as many companies have experienced that both time and cost can be saved in a big way and thus the requirement for manpower for such a job is nil. Cobots note the detection of any defects in the manufactured pieces while packing consistently unlike humans who get worn out during the process. For details click here.

Cobot’s flexibility towards adapting towards any kind of workplace is an added incentive. Their manageable weight and size, less power consumption for them to work efficiently and their capacity to be moved from one application to another without any hassles are the added advantages of a Cobot. Their appreciable level of consistency towards performing any task is commendable. To know more, click here.

Future of Cobots in Manufacturing Industry

The economic growth to selling of Cobots is believed to be rising and is expected to have an increase of 34% by year 2026. Robotics Industries Association also has informed of a very high number of Robots has been exported to companies in Northern America in early 2018 of which Cobots are only 3%. This is believed to be due to the reason of Cobots still being a growing technology. According to the Robotics safety standards, which were inaugurated in the year 2016, Cobots are proven to be “Safe” when they are at a certain distance from people and other equipment.

The safety standards provided by ISO/TS become the point of initiation for many more researches in the field of robotics. At present, along with the already existing research, National Institute of Standards and Technology are conducting studies on how humans can work along side both robots and Cobots. This will in turn give both security and efficiency in the products manufactured.

Cobots in Present Day Manufacturing

Standards in both safety and technology to handle Cobots are evolving with Collaborative robots employed in the immediate vicinity, next to humans in the workplace. At present the need for extra security barrier or defense is not required. A repetitive job, which caused more monotony and wounds to humans are taken over by Cobots even within the safety standards presently set in a more cost-efficient way.

Standards in both safety and technology to handle Cobots are evolving with Collaborative robots employed in the immediate vicinity, next to humans in the workplace. At present the need for extra security barrier or defense is not required. A repetitive job, which caused more monotony and wounds to humans are taken over by Cobots even within the safety standards presently set in a more cost-efficient way.

Cobots are programmed to work right from categorization and wrapping to pasting and sorting of products in the manufacturing industry. Apart from this they are also streamlined to conduct the below tasks

- Examining the Quality of the produce

- Refining the products

- Treatment of machinery for maintenance

- Inoculation of the molding

- Assembly

- Take and keep the products by categorizing

- Inspection of minute auto parts for defects

Every SME should relish the complete advantage of making use of Cobots in their manufacturing units so as to better their output quality, product quality, safety and time management.